Introduction

Establishment of South Rouhina Steel Complex started in 2010 , on a 100 hectares land in Khouzestan province , located in th 7 KM , Dezful - Shoushtar road . Rouhina Steel consisting of two steel rolling mill and steel making factory satisfying domestic needs has the utmost potential to be one of the main exporters of steel products .

Rebar mill : 500/000 ( ton / year ) steel rebar.

Continuous Steel making and Rolling mill : 450000 ( ton / year ) , Billet and 450000 ( ton / year ) , Steel rebar . will be in operation in 2019 An outstanding feature of Rouhina Steel is the integration of steel making and rolling mill plants in hot charge continuous casting process from sponge iron up to rebar .

Continuous " Hot Charge " feed , results in up to 30 % decrease in plants's energy consumption .

Rouhina Steel consisting of two steel rolling mill and steel making factory satisfying domestic needs has the utmost potential to be one of the main exporters of steel products.

Goals

South Rouhina Steel Complex, relying on the grace of The Almighty, advanced global knowledge, employee's enthusiasm and efforts, correct management and efficiency of world class and state of the art technology for the authority and prestige of this country has been presented in domestic and foreign markets with production of various quality steel products.

The most important headlines for this goal are:

- Production and supply of diverse and high quality steel products

- Dynamism in the direction of development

- Participation in domestic and global markets

- Economic production

- customer satisfaction

- Environmental commitment

- Adherence to correct production and productivity management

Rebar mill

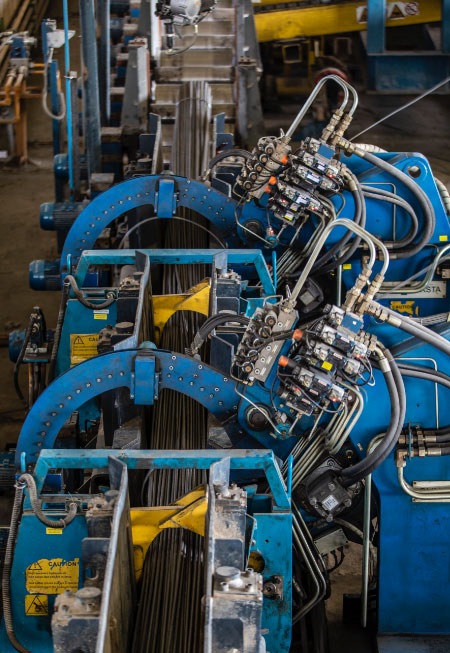

This production line by having high-Technology equipment , Consumes 150x150 mm billets with the annual Capacity of 500/000 ( ton / year ) producing various grades of (A1,A2,A3,A4,BS500,ASTM,GR60,GR75) sizes 8-40 mm

Design , Engieering and Erection

All equipment for production line , furnace , Cranes , Water Treatment Plant ( WTP ) , etc. Were supplied by DANIELI of italy and Execution and Erection activities , under supervision of DANIELI's supervisors , were performed by highly experienced Iranian engineers and technicians . An important feature of this production line is head to head welding of the billets or the Billet welder machine . This process decreases the amount of scraps on raw material .

Line Equipment:

- Preheating furnace , 80 t / h

- Quenching

- Cooling bed

- Shears

- Billet Welder

- Production line equipment

- Billet descaler

- Bundling and weighing system

- Initial, Intermediate and Finishing rolling stands

- All equipment is working under a high - level automation system to reach a high quality product

Continous Steel making and Rolling mill (MIDA)

Consuming mixed of sponge iron “ DRI ” and iron scraps as raw material with the capicity of 450000 (ton/year), this plant is capable of producting various grades steel rebars (A1,A2,A3,A4,BS500,ASTM,GR60,GR75) in sizes 8-40 mm. Utilizing the unique technology and engineering which is paterned by DANIELI, the preheating furnace has been omitted and rebars are produced directly from sponge iron “ DRI “ and iron scaps. This state of the art technolo- gy wich is third in the world, due to remarkable economizing of energy consumption and by omitting intermediate stages of steel making and rolling, is also well known as the “production of green steel”

Main Equipment:

- Charging System (Sponge Iron and Scrap Iron)

- Fume Processing Plant (FTP)

- Electric Arc Furnace (EAF) 68 t/h

- Ladle Furnace (LF)

- Continuous Casting Machine (CCM)

- Induction Furnace

- Billet Shears

- Initial,Intermediate and finishing rolling stands

- Quenching

- Shears

- Bundling & Weighting system

- Cooling bed